सभी उत्पाद

-

औद्योगिक रबड़ शीट

-

सिलिकॉन रबर शीट

-

उच्च तापमान रबर शीट

-

सिलिकॉन ट्यूब एक्सट्रूज़न

-

सिलिकॉन रबड़ वाशर

-

पॉलिनेरथन युग्मन

-

पीटीएफ पैकिंग

-

PTFE गैसकेट टेप

-

PTFE लेपित शीसे रेशा कपड़ा

-

PTFE मेष

-

PTFE ट्यूबिंग

-

रबर शॉक माउंट्स

-

रंगीन प्लास्टिक शीट

-

नायलॉन प्लास्टिक रॉड

-

ऑयल प्रूफ पेपर

-

ईपीडीएम फोम शीट

-

पीवीसी कन्वेयर बेल्ट

-

औद्योगिक तेल सील

-

पीटीएफई कटर पैड

Kevlar Packing Coated with PTFE The Ultimate Sealing Material for High-Performance Applications in Industrial Equipmen

| उत्पत्ति के प्लेस | चीन |

|---|---|

| ब्रांड नाम | 3A Rubber |

| प्रमाणन | ISO9001 |

| मॉडल संख्या | 3A3005 |

| न्यूनतम आदेश मात्रा | 20kgs |

| मूल्य | USD15.00 per kg |

| पैकेजिंग विवरण | रोल, कार्टन और पैलेट में पैकिंग |

| प्रसव के समय | खरीदार का भुगतान प्राप्त होने के 7-15 दिन बाद |

| भुगतान शर्तें | एल/सी, डी/ए, डी/पी, टी/टी, वेस्टर्न यूनियन, मनीग्राम |

| आपूर्ति की क्षमता | 100000 किग्रा / माह |

निःशुल्क नमूने और कूपन के लिए मुझसे संपर्क करें।

WhatsApp:0086 18588475571

वीचैट: 0086 18588475571

स्काइप: sales10@aixton.com

यदि आपको कोई चिंता है, तो हम 24 घंटे ऑनलाइन सहायता प्रदान करते हैं।

xउत्पाद विवरण

| दबाव | 0 ~ 4MPA | रासायनिक प्रतिरोध | उत्कृष्ट |

|---|---|---|---|

| तन्यता ताकत | 25 एमपीए | सतह | चिकना |

| चौड़ाई | 3-100 मिमी | रासायनिक | प्रतिरोध |

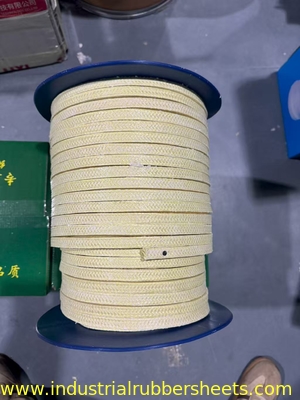

| संरचना | जालीदार चोटी | पैकिंग | कार्टन, लकड़ी के बक्से |

| प्रेस | 3-30MPA | लचीलापन | अच्छा |

| वर्किंग प्रेस | 2-20 एमपीए | प्रस्तुत | सीएनसी मशीनिंग |

| आकार | पैकिंग | ढांकता हुआ | स्थिर |

| प्रमुखता देना | Kevlar PTFE packing seal,PTFE coated industrial packing,high-performance Kevlar sealing material |

||

आप अपनी ज़रूरत के उत्पादों को टिक कर सकते हैं और हमारे साथ संदेश बोर्ड में संचार कर सकते हैं।

उत्पाद विवरण

Kevlar Packing Coated with PTFE - The Ultimate Sealing Material for High-Performance Applications in Industrial Equipment

| Attribute | Value |

|---|---|

| Pressure | 0~4mpa |

| Chemical Resistance | Excellent |

| Tensile Strength | 25 MPa |

| Surface | smooth |

| Width | 3-100mm |

| Chemical | Resistance |

| Structure | lattice braid |

| Packing | Carton, Wooden Box |

| Press | 3-30Mpa |

| Resilience | Good |

| Working Press | 2-20Mpa |

| Produced | CNC machining |

| Shape | Packing |

| Dielectric | Constant |

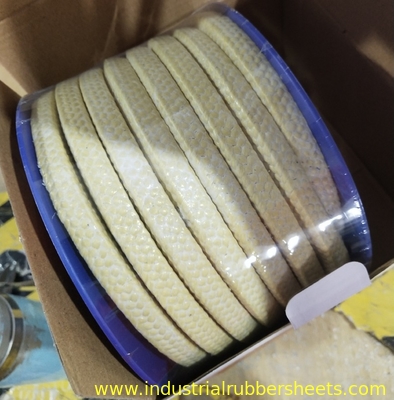

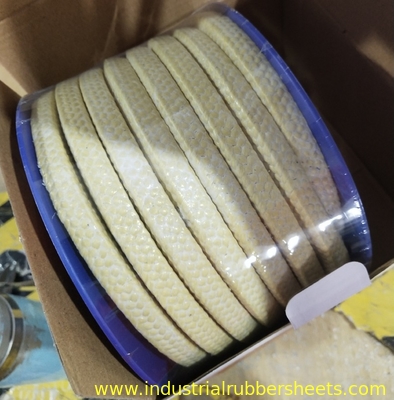

Yellow Pure Kevlar Packing, Kevlar Braided Packing, Kevlar Packing Coated PTFE

Kevlar packing is a type of mechanical sealing material used to prevent leakage in pumps, valves, and other industrial equipment with rotating or reciprocating shafts. It is made from braided fibers of Kevlar® (an aramid fiber developed by DuPont), which is renowned for its exceptional strength, thermal stability, and resistance to abrasion. Unlike traditional packings like flax or graphite, Kevlar packing is a high-performance synthetic material designed to handle more demanding conditions.

Key Advantages and Properties

Kevlar packing offers a unique set of properties that make it superior to many traditional materials:

- Exceptional Strength and Toughness: Kevlar has a very high tensile strength (about 5 times stronger than steel on an equal-weight basis). This makes the packing highly resistant to extrusion, blowout, and wear, leading to a longer service life.

- Excellent Thermal Stability: It can operate continuously at temperatures up to 550°F (288°C) and can handle short-term spikes up to 800°F (427°C). This makes it suitable for hot water, steam, and other high-temperature fluids.

- High Chemical Resistance: It is resistant to a wide range of chemicals, including most solvents, oils, and acids (though it is not recommended for strong acids and strong alkalis).

- Low Coefficient of Friction: Kevlar fibers are inherently lubricious. This reduces friction and wear on the equipment's shaft or sleeve, which lowers power consumption and prevents damage to expensive components.

- Non-Abrasiveness: Unlike some reinforced materials, it is gentle on shafts and won't score or wear them down prematurely.

- Non-Asbestos & Environmentally Friendly: Kevlar packing was developed as a direct, superior replacement for hazardous asbestos-based packing.

Common Applications

Kevlar packing is versatile and used across numerous industries for sealing:

- Centrifugal and Rotary Pumps: Handling hot water, chemicals, slurries, and hydrocarbons.

- Valves: Especially in steam valves, gate valves, and control valves.

- Mixers and Agitators: Where abrasion resistance and strength are critical.

- Expansion Joints: For its flexibility and thermal properties.

- Industrial Equipment: In paper mills, chemical processing plants, power generation facilities, and marine applications.

Common Media Sealed: Hot water, steam, chemicals, acids, alkalis, oils, fuels, solvents, air, dyes, and many other aggressive fluids.

Types and Construction

Kevlar packing is rarely made from 100% Kevlar fibers. It is typically braided and combined with other materials to enhance its properties:

- Pure Kevlar Braid: Braided from 100% Kevlar yarn, often impregnated with a lubricant like PTFE (Teflon) or a proprietary grease. Excellent for general high-temperature service.

- Kevlar/PTFE Blend: Combines the strength of Kevlar with the incredible chemical resistance and low friction of PTFE. This is an extremely popular combination for a wide range of chemical services.

- Kevlar/Graphite Blend: Incorporates graphite for superior lubricity and higher temperature performance, ideal for demanding steam applications.

- Kevlar/Carbon Blend: Offers enhanced thermal conductivity and additional lubricity.

The packing can be square braided, braided over a core (jacketed), or interbraided with other materials.

Installation and Break-in Procedure

Proper installation is crucial for performance and longevity:

- Clean the Stuffing Box: Remove all old packing remnants and clean the shaft/sleeve.

- Measure and Cut: Precisely measure the shaft diameter and stuffing box bore to cut new rings. Always cut rings at a 45-degree angle (skive cut) and stagger the joints around the shaft.

- Install Rings: Carefully install each ring, using a tamping tool to seat each one firmly. Avoid twisting or distorting the rings.

- Adjust the Gland: After installation, hand-tighten the gland nuts.

- Break-in Period: This is critical. Start the equipment and gradually tighten the gland follower in small increments (e.g., 1/6 of a turn) every 10-20 minutes. The goal is to allow a few drops of leakage to cool and lubricate the packing. Never overtighten to stop all leakage immediately, as this will cause rapid, destructive overheating.

- Final Adjustment: Once the packing has settled and run-in (which can take several hours), adjust the gland so there is a minimal, controlled weep of fluid.

Limitations and Considerations

- Not for Strong Acids/Bases: While chemically resistant, prolonged exposure to strong mineral acids (e.g., sulfuric, nitric) and strong caustics (e.g., sodium hydroxide) can degrade the fibers.

- UV Degradation: Kevlar can degrade under prolonged exposure to ultraviolet light, but this is rarely an issue in an enclosed stuffing box.

- Cost: It is more expensive than traditional materials like graphite or flax, but its longer life and reduced downtime often result in a lower total cost of ownership.

Comparison Table: Kevlar vs. Other Common Packings

| Property | Kevlar Packing | Graphite Foil | PTFE (Teflon) | Cotton/Flax |

|---|---|---|---|---|

| Max Temp | 550°F (288°C) | 1000°F+ (538°C+) | 500°F (260°C) | 250°F (121°C) |

| Strength | Excellent | Poor | Good | Fair |

| Abrasion Resistance | Excellent | Fair | Good | Fair |

| Chemical Resistance | Very Good | Excellent | Excellent | Poor |

| Shaft Wear | Low | Can be high | Very Low | Moderate |

| Primary Use | Tough, abrasive, hot services | High-temp steam/air | Broad chemical service | Cold water, oils |

Summary

Kevlar packing is a high-performance, durable sealing solution ideal for applications that combine high pressure, high temperature, and abrasive media. Its unique blend of strength, thermal stability, and chemical resistance makes it a go-to choice for upgrading from traditional packings and solving difficult sealing challenges in demanding industrial environments. Always consult the manufacturer's specifications for your specific fluid, temperature, and pressure conditions.

अनुशंसित उत्पाद